Grating

GRATINGGUIDE TO SELECTION

GRATINGS

Gratings are available in an variety of materials such as: steel, aluminum, fiberglass, powder-coated steel, stainless steel, and galvanized steel.

Gratings are typically used for all types of platforms, mezzanines, flooring, walkways, trenches, and more along with vertical applications such as partitions, fencing and infill panels.

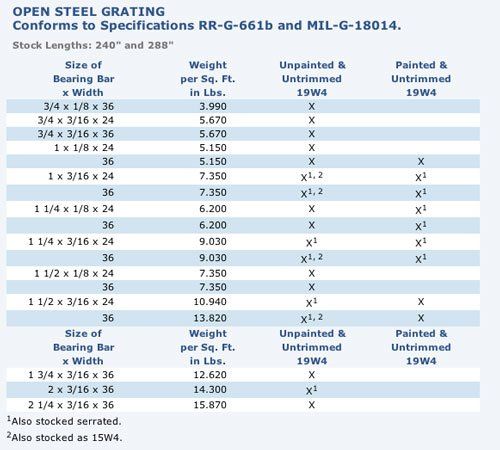

BAR GRATING - Bar grating is a top choice for strength, safety, and long-term cost. Bar Grating consists of a series of bearing bars welded (or otherwise joined) at various intervals to perpendicular cross bars to form a load-bearing panel. Panels are manufactured by welding, locked by swaging, or press-locked processes. A typical panel configuration has bearing bars that are spaced 1-3/ 16 inches (center to center) with perpendicular cross bars spaced 4 inches apart (center to center). Other spacings are available to meet your loading and open area requirements. Bar Grating is available in a wide selection of panel sizes; bar sizes and spacings; bar shapes; and material types. The most popular style is Welded Bar Grating.

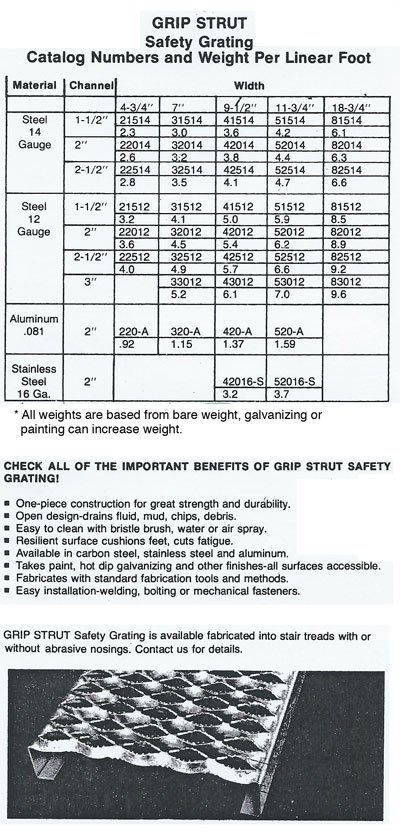

PLANK - Plank Grating is a one-piece construction product that allows easy field handling and cutting. The construction is formed and punched sheet metal or aluminum extrusion. The formed metal planks are available in galvanized, stainless, and plain steel and aluminum. These versatile planks come in a variety of heights and widths for almost every application. Plank styles include a variety of channel configuration choices, some with interlocking choices, and walkway styles with integral toe plates. Plank choices include gratings with surface openings that are diamond, rectangular, slotted, or round shaped, along with solid surfaces. Most plank gratings are lightweight and offer significantly higher slip resistance surfaces than bar grating styles.

EXPANDED - For an economical solution for lighter traffic ramps, walkways, treads or other types of structural applications – consider expanded grating or expanded catwalk. The open diamond truss configuration is a much heavier gauge than regular expanded metal and provides sure footing. With expanded grating, the width of the sheet is parallel to the short way of the diamond opening, the length is parallel to the long way of the diamond opening. With expanded catwalk, the opposite is true – the short way of the diamond runs parallel to the length of the sheet (typically 10 foot) and the long way of the diamond/opening runs the short dimension of the sheet. Catwalk is structurally stronger because the long way of the diamond runs across the shorter supported span. Expanded Grating is available in plain steel styles ranging from 3 to 6.25# per square foot; catwalk grating, 4.27# per square foot; aluminum expanded grating, 2# per square foot.

PULTRUDED - Pultruded Fiberglass Bar Gratings are manufactured with a high percentage of glass within the laminate that provides high strength and stiffness and has a higher load capacity than molded fiberglass grating. It is an ideal replacement for steel or aluminum gratings because it is lighter, corrosion resistant and fire retardant. The bearing bars for these grating panels are shaped in either an I-bar, T-bar or rectangular-bar configuration. Pultruded fiberglass grating panels come in a variety of resins and colors and are available with or without a slip resistant gritted surface.

MOLDED - Molded fiberglass grating is the product of choice where corrosion resistance or fire retardancy is paramount and high impact resistance is important. When compared to steel, this product is very lightweight. Molded one-piece construction panels have a comfortable concave slip resistant walking surface and are easily cut in the field. Load bearing bars in both directions allow for use without continuous side support. Styles include the standard square mesh and rectangular mesh configurations in a variety of sizes, resins and colors. To enhance the slip resistance of the standard concave surface this product is also available with a slip resistant gritted surface. Square molded fiberglass gratings are offered in a smooth, meniscus or grit surface. Square molded fiberglass gratings "with grit" have a higher level of grit content for increased durability and abrasion.

ABOUT US

We are proud of our longstanding commitment to innovation and providing quality customer metal fabrication and finishing services for an extensive range of applications and industries. L and L Metal Fabrication offers unique design build services to expedite the installation of your custom metal products and equipment.”

Copyright © 2019 L&L Metal Fabrication

Designed and Developed by Freedom Digital Solutions

All Rights Reserved | Privacy Policy